Case Study: VCI vs Wax vs HDD Solutions for Pipeline Casing Remediation

By Derek Dickens, Business Development Manager, ZERUST® Integrity Solutions

Introduction: The Challenge of Pipeline Casings

Pipeline casings are notorious in the industry for causing headaches to operators. Let’s face it, nobody likes casings except those tasked with fixing them. They are often job security for corrosion specialists. On average, there is one casing for every seven miles of pipeline.

Over time, casings often develop corrosion due to multiple issues:

-

Ground movement dislodges spacers, leading to metallic contact shorts

-

Compromised seals or holes in the casing allow groundwater and contaminants to enter, driving microbial corrosion

-

Atmospheric corrosion occurs in the void space between the carrier pipe and casing

Why Casings Exist

Casings protect pipelines when crossing under roadways, waterways, railroads, or other structures. They shield the carrier pipe from environmental stresses.

Recently, some companies have shifted to thick-wall, deep HDD (horizontal directional drilling) installations to bypass casing use altogether. While effective, this option is costly and time-intensive, creating financial and operational strain.

Time Constraints and Regulations

Once an issue is detected, operators have 18 months to resolve it. This may seem like plenty of time, but permitting, weather, budgets, and access quickly reduce that window.

Remediation is governed by AMPP SP200-2023, which outlines two primary options:

-

Remove, Replace, or Re-Route the casing and/or carrier pipe

-

Fill the casing with an approved material:

-

Wax Petrolatum System

-

Gel + Vapor Corrosion Inhibitor (VCI)

-

ZERUST® Recommendation: Pre-Excavation Testing

Before excavation, ZERUST® recommends performing simple tests that may eliminate unnecessary digs:

-

Mild pressure test

-

Air exchange check

-

Vent video inspection

These can save both time and money for the operator to determine if the casing endseals are in good condition and whether the casing is a candidate for non-excavation based solutions.

Case Study: Natural Gas Pipeline in Mid-Central U.S.

-

Pipeline Type: Natural Gas

-

Casing Size: 18” casing, 250’ length, with 10” carrier pipe

-

Issue: End-seals compromised, spacers shifted, carrier pipe contacting casing, creating a metallic short and reducing cathodic protection effectiveness

Option 1: Thick-Wall HDD Bore

-

Approach: Remove old casing and pipe, re-bore at 320’ length

-

Timeline: 43 days

-

Cost: $530,000 USD

Option 2: Wax Fill

-

Approach: Repair end-seals, spacers, vents, then inject 1,250 gallons heated wax

-

Timeline: 8 days

-

Cost: $126,000 USD

-

Considerations: Requires specialized crews, wax cools and shrinks leaving voids

Option 3: VCI Fill (Chosen Solution)

-

Approach: Repair end-seals, spacers, vents, inject 1,250 gallons VCI gel. Install RMU with ER probe for monitoring compliance

-

Timeline: 8 days

-

Cost: $138,000 USD

Why VCI Was Selected

Although wax was slightly less expensive, the operator chose ZERUST® VCI due to long-term reliability and monitoring advantages.

Key Benefits of ZERUST® VCI:

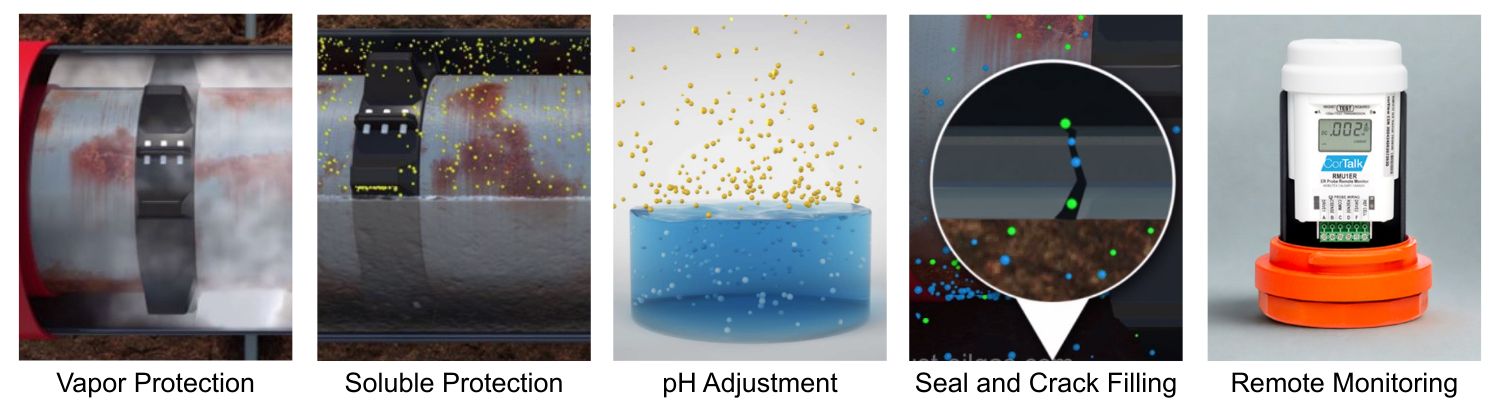

1. Vapor Protection: Inhibitor vapors protect atmospheric spaces within the casing, preventing void corrosion

2. Soluble Protection: Contact Inhibitor bonds directly to steel surfaces, protecting even non-vaporized areas

3. pH Adjustment: Raises annular pH from ~6.5 to ~9.5, making it difficult for most acidic/microbial based corrosion to exist and propagate

4. Seal and Crack Filling: Gel solution fills end-seal cracks and plugs holes up to ½”

5. Remote Monitoring: Continuous oversight via RMU allows operators to track performance and comply with PHMSA Mega Rule requirements without costly field visits

Long-Term Advantages

-

Ease of Removal: VCI gel can be flushed or vacuumed out, unlike hardened wax

-

Re-Injectable: After ~20 years, solution can be refreshed without full replacement

-

Remote Monitoring: RMU allows continuous oversight without field visits, reducing costs and improving compliance

Additional Flexibility

-

VCI can be blown-In, in a powder form: For temperature, slope or weight-sensitive applications such as aerial casings

-

Glycol Additives: For non-buried casings with temperature concerns

Cost and Time Savings

If no repairs were required, the VCI solution could have been implemented in less than one day at a cost of only $42,000 USD.

Compared to HDD boring at $530,000 USD over 43 days, VCI provided:

-

74% cost reduction

-

Nearly one month of time savings

Conclusion

This case demonstrates how ZERUST® VCI offers pipeline operators a cost-effective, compliant, and long-term alternative to wax or HDD boring. With corrosion protection, pH adjustment, and built-in monitoring, VCI provides both immediate remediation and future-proof reliability.

Looking Ahead

Pipeline casing remediation does not have to be complicated or cost-prohibitive. This case study highlights how evaluating multiple options can reveal solutions that save both time and money while meeting regulatory requirements. ZERUST® technology provides a reliable, flexible, and sustainable approach that operators can trust for long-term integrity management.

For more details on how VCI solutions may fit into your pipeline integrity program, click here to reach out to the team at ZERUST® Integrity Solutions.