Corrosion Technologies

Corrosion Technologies

ZERUST Integrity Solutions® technologies have been successfully deployed in refineries, oil rigs, and tank farms worldwide. By integrating our proprietary ZERUST® inhibitor formulations with conventional corrosion mitigation methods - such as cathodic protection and coatings - we deliver advanced, innovative solutions that effectively address costly corrosion challenges.

Our corrosion engineers take protection a step further with our comprehensive Integrated Corrosion Technologies (ICT) system. Backed by years of experience, our experts work with you to select the optimal VCI solution tailored to your specific application.

Vapor Corrosion Inhibitors (VCIs) and Soluble Corrosion Inhibitors (SCIs).

ZERUST Integrity Solutions is a global leader in corrosion protection for bare metals, specializing in Vapor Corrosion Inhibitors (VCIs) and Soluble Corrosion Inhibitors (SCIs).

These technologies offer clean, effective protection without the need for greases or coatings, making them ideal for preserving metal parts and equipment during storage, transport, or operation.

Trusted worldwide, ZERUST VCIs and SCIs have been proven safe and effective in extending the life of critical assets.

How do VCIs and SCIs work? Click Here to watch a video to find out.

ZERUST® Zerion™ FVS

ZERUST Zerion FVS is a highly cost-effective corrosion mitigation solution designed for hard-to-protect areas. It is ideal for use in applications such as the soil-side of aboveground storage tanks, tank pontoons, enclosed voids, large equipment, pipeline layup and casing protection, hydrostatic testing, offshore risers, and long-term preservation or mothballing scenarios.

ZERUST Zerion FVS provides two layers of protection:

- Vapor Corrosion Inhibitors (VCIs): safeguard internal air spaces and exposed metal surfaces, particularly in welded joints, crevices, and coating defects.

- Soluble Corrosion Inhibitors (SCIs): combat corrosion caused by moisture accumulation or water ingress.

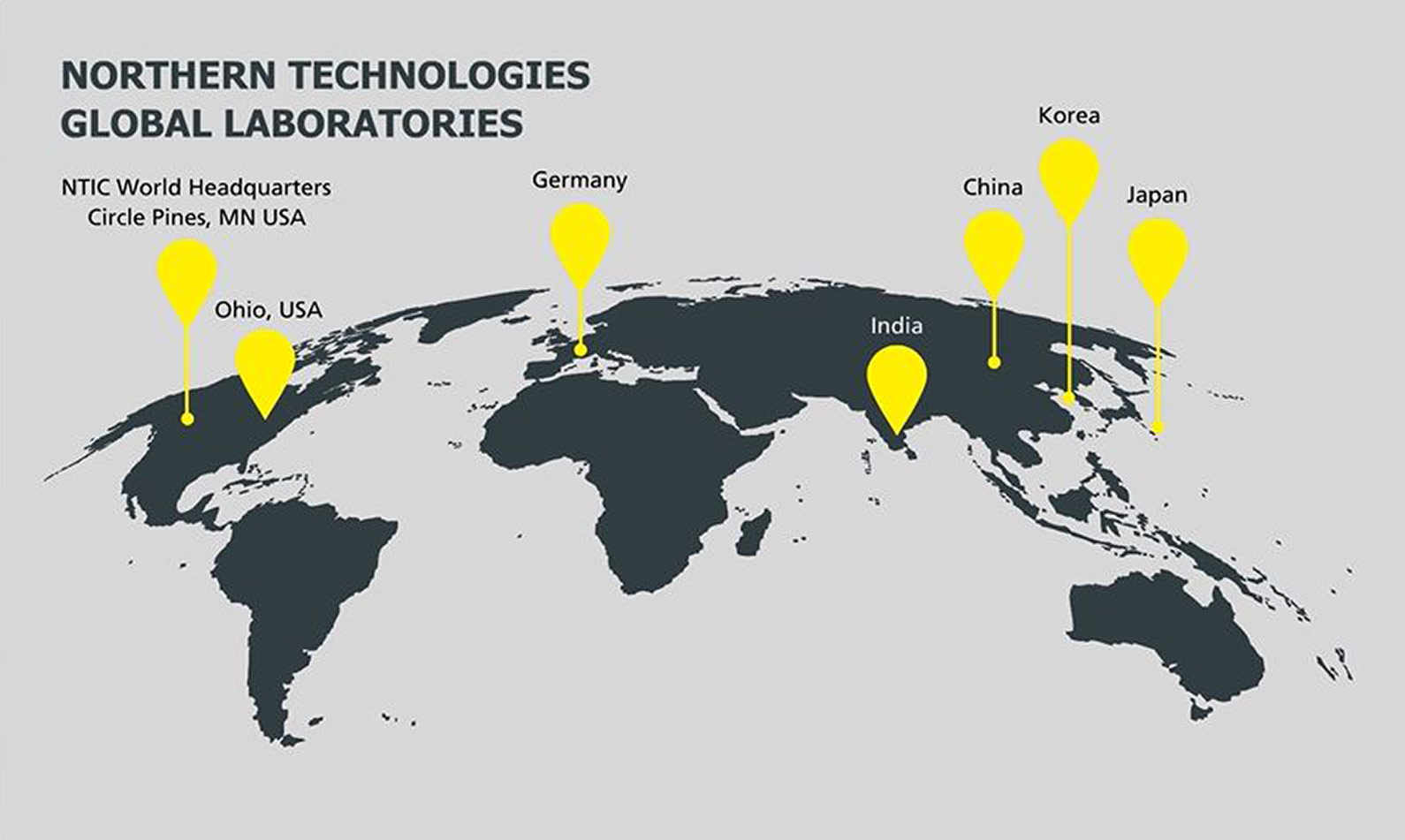

Laboratories and Test Facilities Across the Globe (R&D)

Field trials and rigorous R&D lab testing are continually performed to evaluate and enhance the performance of our corrosion protection solutions. Our laboratory team uses advanced equipment to conduct accelerated testing in a wide range of corrosive environments across multiple industries, including conditions containing Hydrogen Sulfide (H₂S), Sulfur Dioxide (SO₂), and Carbon Dioxide (CO₂).

The ZERUST team has state of the art laboratory facilities in Beachwood, Ohio (USA) and in Circle Pines, Minnesota (USA) that are used for primary corrosion research, product development, and joint R&D with our clients and analysis of field test data. ZERUST Integrity Solutions also has access to worldwide regional ZERUST®/Excor® technical support centers.