Above Ground Storage Tanks

ZERUST® Integrity Solutions provide a cost-effective means to mitigate underside corrosion of aboveground storage tanks while the tanks are in or out of service.

Soil Side Bottom Protection

In or Out of Service Tank Solutions

Out-of-Service Tanks

Tank Roof Protection

Fixed Roof Tanks

Floating Roof Tanks

ZERUST® VAPOR CORROSION INHIBITORS (VCIS)

For more information,

Contact Us

The Problem

Soil-side bottom (SSB) corrosion is a leading cause of premature failure in aboveground storage tanks (ASTs), driving up maintenance costs, increasing inspection frequency, and creating risks of environmental damage and revenue loss. Although cathodic protection (CP) systems are commonly used to combat corrosion, they often face limitations such as high soil resistivity, disrupted current flow due to foundation design or environmental conditions, and difficulty reaching voids or complex structures. Over time, additional issues like broken or shorted components can further reduce the effectiveness of CP systems.

The hidden costs of corrosion

Maintenance Expenses

- Purging and cleaning

- Bottom plate replacement

- Release Prevention Barrier (RPB) liner installation

- Frequent inspections

- Lost time during tank servicing

Operation Costs

- Downtime from unlpanned repairs

- Environmental impact

- Revenue loss from out-of-service tanks

- Increased Inspection Requirements

The Solution

ZERUST® Vapor Corrosion Inhibitors (VCIs) provide targeted corrosion protection for AST bottoms by releasing corrosion-inhibiting molecules that migrate into hard-to-reach soil-side areas. VCIs are effective on their own or alongside CP systems and are referenced in API 2610 Section 12.5, API TR 655, and AMPP SP21474.

Why choose ZERUST® vcis - proven, cost-effective protection

- Comprehensive protection for voids, interstices, and soil-side tank bottoms

- Minimal surface preparation needed in most applications

- Uniform dispersion for consistent coverage

- Cost-effective solution that extends tank bottom life

- Eco-friendly and non-permanent corrosion protection

- Inspections and maintenance can be completed without halting operations

- VCIs backed by API and AMPP standards, with proven field results

- Helps reduce total maintenance costs and avoid costly downtime

api-referenced standards for vci technology

ZERUST® Vapor Corrosion Inhibitors (VCIs) are recognized in API 2610 Section 12.5 as an effective corrosion mitigation method. Additionally, API Technical Report 655 (API TR 655) details the application and use of VCIs for soil-side corrosion protection of AST bottoms. AMPP SP21474 further details options for mitigating corrosion under tank bottoms. This approach offers comparable performance to cathodic protection systems and is supported by extensive PRCI (Pipeline Research Council Int’l) testing and field data. For more details, contact a ZERUST® representative. For more information, click here.

VCI and CP Compatibility

While the DOT - PHMSA does not currently allow the use of VCIs without Cathodic Protection (CP) for “break-out” tanks, most State-regulated tanks may use VCIs independently or in scenarios where CP is limited or inapplicable, as outlined in API 651. In these cases, VCIs provide an effective alternative corrosion protection solution.

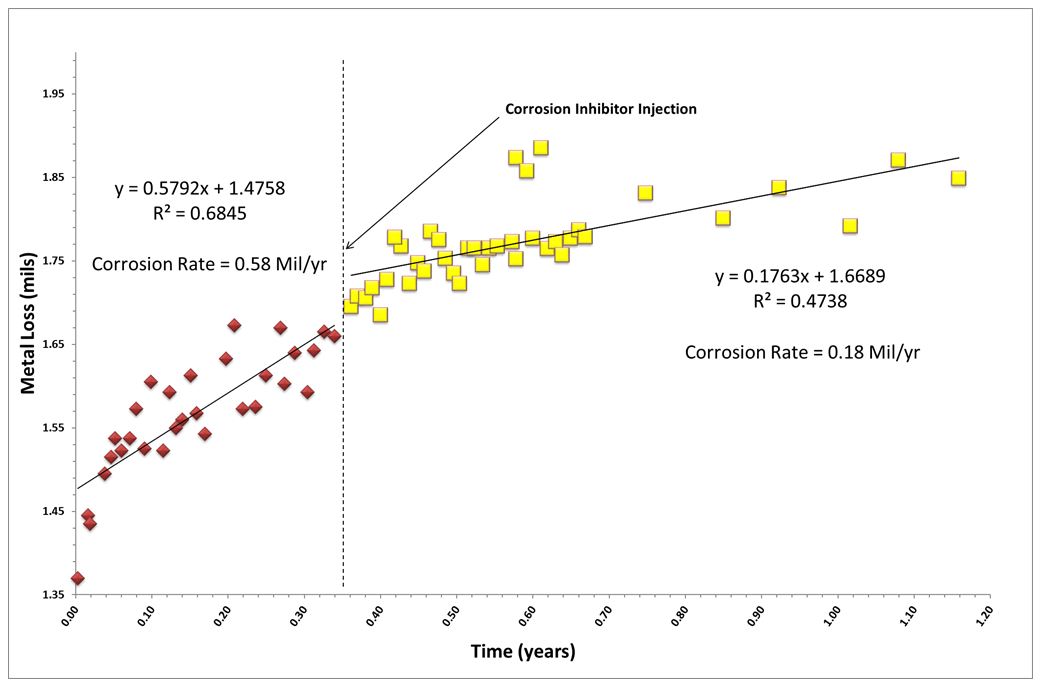

CORROSION monitoring with er or ut probes

Electrical Resistance (ER) and Ultra-Sonic Thickness (UT) probes measure the corrosion rate in the sand or soil foundation beneath a tank. Baseline corrosion rates are established by tracking resistance changes over time. VCI vapors emitted from the solution protect the ER probes, demonstrating the inhibitor’s effectiveness. Probe tubes are installed at various points to estimate bottom plate corrosion. The probe cables are stored outside the ring wall, enabling corrosion readings without interrupting tank operations.

Implementing the Corrosion Solution

Every proposal for a Tank Bottom corrosion mitigation solution starts with custom-design work that thoroughly evaluates the construction details for a targeted asset. Based on those factors, an Inhibitor Delivery System (IDS) is selected for implementation. ZERUST® IDS were designed to allow for the application of our corrosion inhibitor compound to a variety of different environments and construction types. ZERUST® offers a variety of tank Inhibitor Delivery System (IDS) options that are detailed on the following pages.

Chime Ring Dry

ZERUST® Chime Ring Dry Inhibitor Delivery System (IDS) solution is specifically designed for storage tanks with concrete ring walls, offering targeted corrosion protection for the chime and annular ring. This innovative system utilizes a ZERUST® VCI/SCI (Soluble Corrosion Inhibitor) application method, where VCI dry sleeves are strategically placed at the chime-concrete interface and sealed to form a protective enclosure.

The VCIs migrate via vapor pressure under the tank’s edge and adsorb onto metal surfaces, delivering effective corrosion protection. This diffusion process safeguards the critical 10 to 15 feet of metal from the tank edge, ensuring long-term durability in this vulnerable area.

FOUNDATION(S): CONCRETE, BITUMEN, COMPACTED SAND OR SOIL.

Chime Injection

ZERUST® Chime Injection IDS is ideal for storage tanks with concrete, bitumen, or asphalt pads with liner foundations. This ZERUST® VCI/SCI injection system protects tank bottoms using various injection methods, including the tube system shown or other owner-approved designs.

As the inhibitor slurry is pumped into the system, VCIs migrate to metal surfaces while the slurry neutralizes contaminants on the bottom plates or foundation. Together, ZERUST® VCIs and SCIs provide effective, long-term corrosion protection for vulnerable tank bottom areas.

FOUNDATION(S): CONCRETE, BITUMEN, COMPACTED SAND OR SOIL (ALL FOUNDATIONS MUST INCLUDE A LINER OR RPB).

Underside Injection

ZERUST® Underside Injection IDS (the most common method of VCI application) is designed for tanks with compacted sand fill, Release Prevention Barriers (RPBs), double bottoms, or hard pads like concrete or asphalt.

A low-viscosity inhibitor solution is injected through ring wall ports, with ZERUST® SCIs neutralizing contaminants and ZERUST® VCIs migrating to protect the metal surface. The ZERUST® VCIs spread through the sand bed via capillary action and gravity, ensuring full tank floor protection.

FOUNDATION(S): CONCRETE, BITUMEN, COMPACTED SAND OR SOIL (ALL FOUNDATIONS MUST INCLUDE A LINER OR RPB).

Internal Flood

The ZERUST® Internal Flood IDS is similar to the Underside Injection application, but is performed through the tank floor, while the tank is out of service.

Low-viscosity inhibitor solution is injected through temporary ports installed at selected locations in the tank floor. The solution emits ZERUST® VCIs that migrate and bond to the metal surface, while ZERUST® SCIs neutralize contaminants on the bottom plates or foundation. Multiple injection points ensure rapid and uniform dispersion of the slurry across the entire tank bottom.

FOUNDATION(S): CONCRETE, BITUMEN, COMPACTED SAND OR SOIL (ALL FOUNDATIONS MUST INCLUDE A LINER OR RPB).

Dry Tube

ZERUST® Dry Tube IDS protects tank bottom plates during construction or new floor installation, ideal for tanks with concrete, bitumen, or compacted sand foundations, with or without liners. Shallow trenches are created to contain perforated, mesh-covered PVC pipes, these trenches are then filled with sand.

The tank chime is sealed to block moisture and contaminants, and ZERUST® VCI-infused dry mesh sleeves are installed in the pipes. This sealed system allows ZERUST® VCIs to rise from the sand, effectively preventing corrosion on the metal bottom plates. Sleeve can be easily replenished as needed in the future.

FOUNDATION(S): CONCRETE, BITUMEN, COMPACTED SAND OR SOIL.

Underside Drip Tube

The Underside Drip Tube IDS protects tank bottom plates in single or double bottom tanks during construction or new floor installation. A network of perforated PVC pipes with geotextile covers are installed in rings atop the tank liner within the sand foundation, with inlet pipes extending through the ring wall for access.

The tank chime is sealed to block moisture and contaminants. Low- viscosity inhibitor solution is injected through the ports, and the PVC pipe network distributes it evenly across the sand bed. VCIs protect the metal bottom plates, while SCIs neutralize contaminants. Injection ports allow for future inhibitor replenishment.

FOUNDATION(S): CONCRETE, BITUMEN, COMPACTED SAND OR SOIL (ALL FOUNDATIONS MUST INCLUDE A LINER OR RPB).

ZERUST® Solutions for Tank Bottom Protection

CASE STUDY: SSB INSTALLATION

ZERUST® successfully demonstrated its Underside Injection IDS solution in a challenging installation where tank operations could not be stopped. This system introduced a liquid inhibitor solution into the sand pad beneath the tank through monitoring ports. The solution spreads evenly across the “deleted” sand bed, releasing ZERUST® VCIs that volatilize to protect the entire soil-side bottom of the tank.

Effectiveness was validated using metal loss readings from ER probes before and after injection. Data collected showed a threefold reduction in the corrosion rate compared to baseline levels, confirming the efficacy of the ZERUST® Underside Injection IDS solution. Refer to the "Metal Loss Versus Time" table below for results.

Metal Loss Versus Time