Pipeline Casing Protection

The Problem

Underground pipelines are required to have cathodic protection to protect them from corrosion. When these pipelines run under roadways, railway lines, etc. they have historically been required to have protective metal casings. Over time, there may be movement of the product carrying the inner pipeline (“carrier pipe”) and/or the casing that brings the carrier and casing into contact. This results in a “metallic short” that causes the cathodic protection current to pass through the casing.

Pipe Casing Protection

For more information,

Contact Us

PROBLEM: Corrosion risks, downtime, and costs

Underground pipelines require cathodic protection, but when enclosed in metal casings under roadways or railways, movement can cause metallic shorts, diverting protection current and increasing corrosion risk.

With hundreds of thousands of cased crossings in North America, many in service for decades, contaminants like moisture and oxygen can accumulate, accelerating corrosion on both the casing and the carrier pipe. Gaps in end seals further expose pipelines to damage.

Regulations require addressing metallic shorts through:

• Excavation and repair ($$$$)

• Filling the casing with wax ($$)

• Applying a VCI gel ($)

Recognized by NACE SP0200-2014, Vapor Corrosion Inhibitors (VCIs) offer a cost-effective solution to protect these vulnerable areas.

Solution: cost-effective vci protection

ZERUST® offers a specialized VCI gel solution injected into the annular space to protect pipelines through:

Soluble Corrosion Inhibitors (SCIs) - Shield surfaces in direct contact.

Vapor Corrosion Inhibitors (VCIs) - Protect the entire annular space.

Since no two cased crossings are alike, ZERUST® engineers customize solutions by adjusting inhibitor concentration and volume based on cost, longevity, and site conditions. Operators can provide key details to receive precise recommendations.

Using VCIs extends pipeline life cost-effectively, with corrosion monitoring via ER probes or coupons.

Installation is often possible through vent pipes with no excavation required.

How ZERUST® CASED pipeLINE PROTECTION WORKS

High-Viscosity Gel Application

Best For: Pipelines with a metallic short (casing in contact with the carrier pipe) or cases requiring a static fill anti-corrosion solution. Meets PHMSA requirements for a protection system that remains in place.

- How It Works:

- Installed as a low-viscosity slurry, which sets into a high-viscosity gel.

- VCIs volatize to protect the vapor spaces, while SCIs neutralize contaminants on contact.

- Bridges small penetrations, reducing leaks and blocking external contaminants.

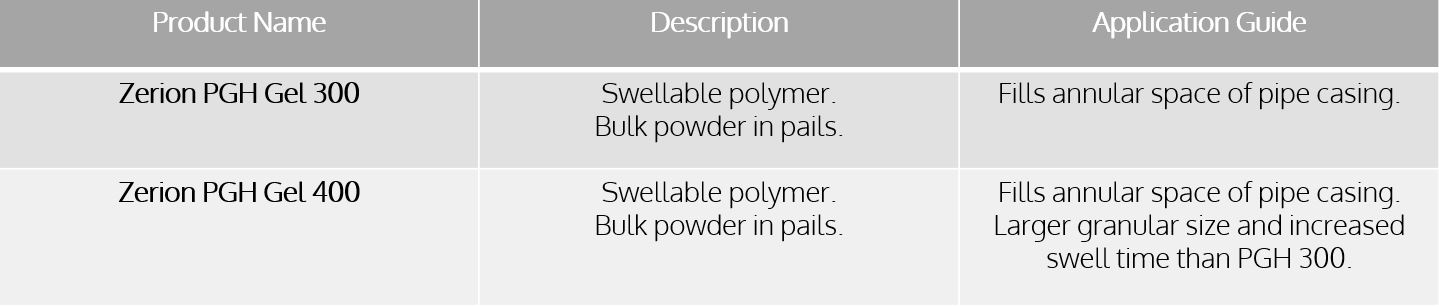

Powder Application

Best For: Pipelines without a metallic short, where internal corrosion protection is a proactive maintenance strategy. Works best when end seals are intact to prevent water ingress.

- How It Works:

- ZERUST® Zerion™ FVS powder inhibitors are blown into the casing via vent pipes using a blower system.

- The powder settles at the bottom, with SCIs neutralizing contaminants and VCIs protecting the vapor space.

- Full annular protection with minimal installation effort.

Slurry Application

Best For: Long pipeline sections with elevation changes, bends, or complex geometries where powder or gel isn’t feasible.

- How It Works:

- ZERUST® Zerion™ FVS is mixed with water and injected via gravity or a low-pressure pump through the casing vent pipe.

- SCIs neutralize contaminants on contact, while VCIs protect the entire vapor space.

- Ideal for longer casings, provided the casing and end seals are intact.

ZERUST® has tailored solutions to ensure long-lasting protection for cased pipelines, preventing corrosion and extending asset life.