Zerion PGH-300 and Zerion PGH-400

ZERUST ZERION PGH-300 and Zerion PGH-400

Protect your pipeline casings with ZERUST® Zerion™ PGH-300 and PGH-400, innovative gels that combine with Zerion™ inhibitors to deliver comprehensive, long-term corrosion protection. Designed to fill annuli, seal small penetrations, and reduce contaminant ingress, these solutions ensure reliable performance even in challenging or complex casing environments.

ZERUST® Zerion™ PGH-300 and PGH-400 are gels engineered for use in pipeline casing annuli. When hydrated with water and Zerion™ corrosion inhibitors, PGH forms a viscous, non-metallic gel that functions as a casing filler to retain inhibitors, bridge small penetrations in the casing, and reduce ingress of external moisture and contaminants. Combined with Zerion™ FVS soluble corrosion inhibitors (SCI) and vapor corrosion inhibitors (VCI), the system provides comprehensive protection to carrier pipes within metallic casings.

Typical applications

Recommended uses for ZERUST® Zerion™ PGH-300 and PGH-400 include (but are not limited to):

• Annuli with metallic shorts or semi-shorts, where filler/inhibitor systems help reduce corrosion potential and supplement CP.

• Geometrically complex or long annuli, where uniform inhibitor distribution and retention are critical.

• Remediation projects where casings cannot be feasibly decoupled or removed, and filler installation is recognized by SP0200 as a corrosion-mitigation option.

KEy advantages

• Retains Zerion™ inhibitors in casings for long-term protection

• Mitigates corrosion in carrier pipes and vapor spaces

• Reduces contaminant ingress through end seals and vents

• Flexible application: gel slurry (preferred), powder (settling release), or dry fill (special cases)

• Easy to handle and compatible with standard casing injection practices

operating summary

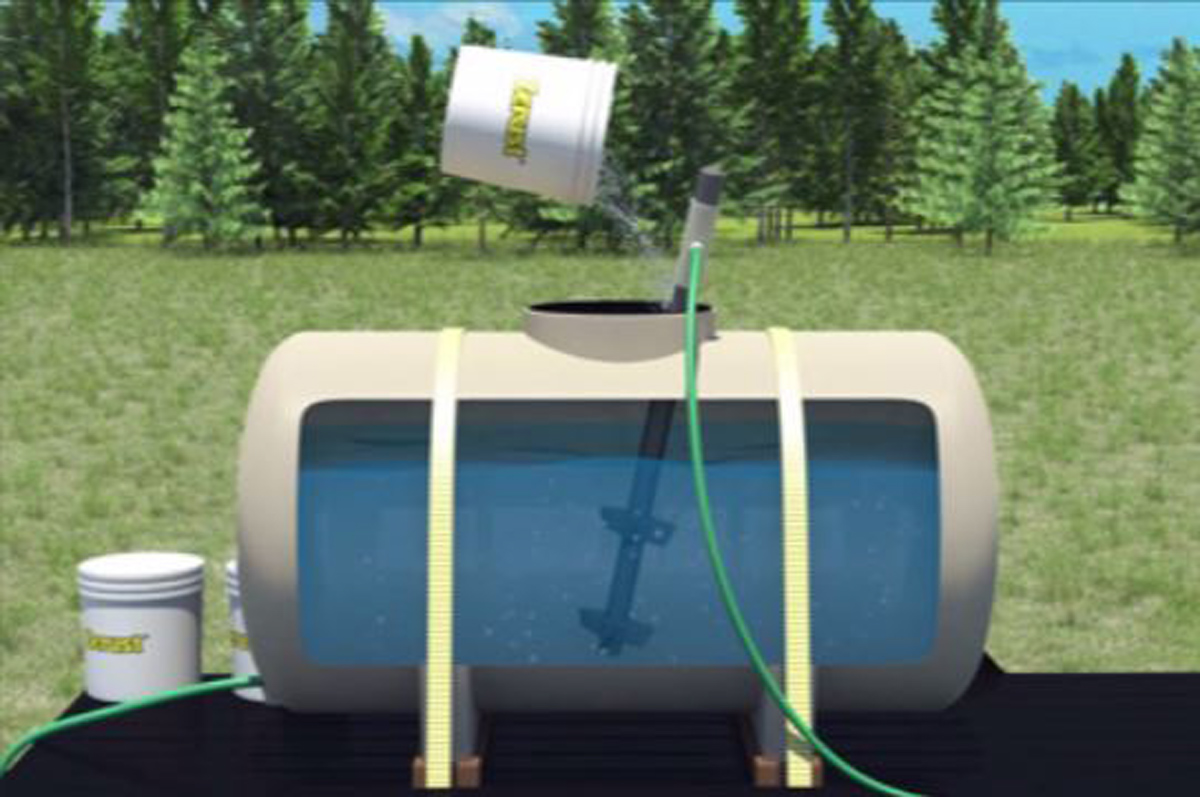

Injection method: Prepare a 5 wt% ZERUST® Zerion™ FVS inhibitor solution in clean potable water. Just prior to injection, introduce ~3 wt% Zerion™ PGH using a hopper/eductor. Avoid premixing and recirculation to prevent premature swelling.

• Filling: Pump the inhibitor–gel slurry into the casing annulus from the low-end vent/port until breakthrough at the high end. Seal vents after fill is confirmed.

• Function: Once hydrated, PGH retains inhibitors in the annulus, raises effective resistivity, and reduces leakage and contaminant ingress. The gel is non-metallic and does not short carrier/casing but can conduct limited ionic current.

• Service life: Protection duration depends on annulus volume, seal integrity, site water chemistry, and dosage. Periodic monitoring (short surveys, ER probes, CP potential) is recommended.

product selection

• ZERUST® Zerion™ PGH-300: Smooth gel consistency; best for static fills and sealing small penetrations.

• ZERUST® Zerion™ PGH-400: Granular texture; improved handling and flow in larger or complex geometries.

• Combined Use: In many casing applications, a blend of PGH-300 and PGH-400 is recommended. Using both grades together allows the system to take advantage of PGH-300’s ability to form a uniform, sealing gel while also leveraging PGH-400’s improved flow characteristics for filling long or geometrically complex annuli. This combination enhances inhibitor distribution, improves void coverage, and provides a more stable annular fill.

*Please contact a ZERUST® representative for specific dosage, application equipment guidance and recommendations.

For typical properties, availability, and more, download the brochure below.